Design Brief

This time we've teamed up with Flexion and MakeShaper to bring you a competition designed to make the most of the awesome properties of MakeShaper 3D printing filaments.

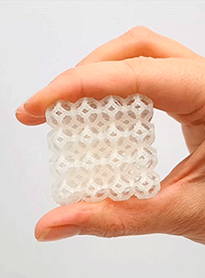

MakeShaper produces a large variety of high-quality filament, and for this competition, we'll be focusing on their flexible materials and their unique properties.

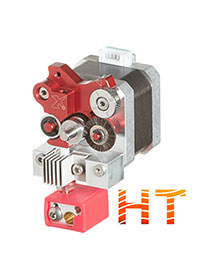

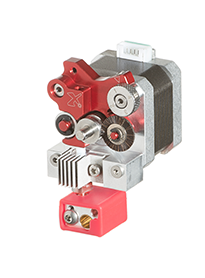

With the Flexion Extruder kit, those at the desktop level should be able to look forward to an exciting upgrade meant to solve numerous issues that the Diabase team saw plaguing the 3D printing space. In addition to excelling with flexible filament, the Flexion processes more rigid materials than other extruders and employs a low-friction, low-clearance barrel to convert stepper motor torque and melt pressure with minimal loss.

The theme for this design challenge is "flexibility", and while quite broad, will encourage you to design with flexible filament in mind and explore the boundaries of your 3D design expertise.

You don't have to only make use of flexibility, but try and incorporate an essence of flexibleness in your design in some way.

We have some awesome prizes to give away, including a Wanhao Duplicator i3, 2x Flexion HT extruders, 1x standard Flexion extruder and filament.

Winning designs will be chosen by a panel of judges from MakeShaper and MyMiniFactory based on creativity, originality, 3D printability and flexibility.

Good luck and have fun!

Once your model has been uploaded to MyMiniFactory, remember to share it to Twitter to the hashtag #Flex3D @MyMiniFactory @MakeShaper.

Submit your design

.png)